Product Center

- Double pendulum head five-axis gantry milling center

- Five-axis gantry-mold machine

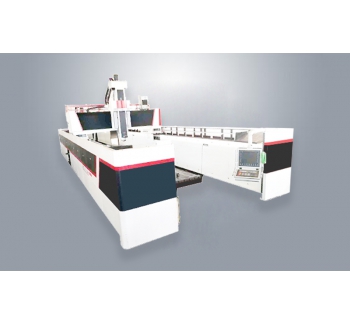

- High-speed crossbeam mobile gantry

- Moving column type Gantry

- Vertical/regional machining center

- High-speed profile/composite machining center

- Aerospace special equipment

- Special equipment for hand tools

- Download Center

Contact Us

address:No. 11 Xiangfeng Road, Jiangning Binjiang Development Zone, Nanjing City Sales Center

Phone:025-84950091

Customer Center Phone:025-84950092

mailbox:ningqing@163.com

search for

1:Imported high-speed and high-precision ball screws, good precision retention and rigidity.

2: The crossbeam is directly connected to the screw through a high-power servo motor to ensure the precision of the machining contour without overcutting phenomenon.

3: The left and right guide rail seat and worktable are separated, and the height of closure can be adjusted freely.

4: Adopt rack and pinion drive for 8 meters and above travel, synchronized dual drive four motor isotropic differential backlash movement structure

5:Small footprint, 60% of the same specifications of the table mobile gantry

6: The use of self-developed composite guide technology to lengthen the cutting resistance moment and bearing area, to enhance cutting resistance

7: The table bearing large, theoretically not subject to weight limitations

CMS split type 25, thirty and above series

parameters | Unit | CMS4025 | CMS6025 | CMS6030 | CMS8030 | CMSXXX35 |

Worktable | mm | 2100x4000 | 2100x6000 | 2600x6000 | 2600x8000 | 3100xXXX |

Max worktable loading | t | 30 | 40 | 50 | 65 | / |

X/Y/Z travel | mm | 4950x2500x1200 | 6950x2500x1200 | 6950x3000x1200 | 8950x3000x1200 | / |

Dist.from spindle nose to table | mm | 350-1550(customizable) | ||||

Max loading height x width | mm |

1500(customizable)x3160

| 1500(customizable)x3600 | |||

Rapid/feeding speed | m/min | 20/0-15 | ||||

Positioning/repeat accuracy | mm |

0.01/0.005 | ||||

Weight of machine | t | 60 | 75 | 78 | 102 | / |

Dimension (without electrical cabinet) | mm | 9080x6320x5750 | 11080x6320x5750 | 12020x6820x5750 | 13020x6820x5750 | / |

Control system | Siemens 828D、Fanuc MF plus,Siemens ONE | |||||

| technical parameter | unit | CMSforty25 | CMSsixty25 | CMS6030 | CMS8030 | CMSXX335 |

| Workbench area | Mm | 2100 × 4000 | 2100 × 6000 | 2600 × 6000 | 2600 × 8000 | 3100 × XXX |

| Maximum load capacity of workbench | t | 30 | 40 | fifty | sixty-five | / |

| Travel in X/Y/Z direction | Mm | 4950 x 2500 x 1200 | 6950 x 2500 x 1200 | 6950 x 3000 x 1200 | 8950 x 3000 x 1200 | / |

| Guide rail form | X: Two parallel four track tracks on each side, Y: two track tracks supported by hard tracks vertically distributed, Z: four roller track tracks distributed in four directions | |||||

| Spindle end face to worktable | Mm | 350-1550 (customizable) | ||||

| Mechanical belt spindle can be installed And motor | Standard belt BT50-190-6000, optional+dual speed gearbox (BT50-190-8000) | |||||

| Siemens 28/42kw (rated 1000rpm) 267.5/401Nm (optional+ZF gearbox 1070/1604Nm) | ||||||

| Spindle optional transmission mode | Built in short direct connection BT50-190-6000, optional+dual speed gearbox | |||||

| Maximum loading height x width | Mm | 1500 (customizable) x 31601500 (customizable) x 3600 | ||||

| Rapid movement/feed rate | M/min | 20/0-1530/0-15 | ||||

| Positioning/Repetitive positioning accuracy | Mm | 0.01/0.005 | ||||

| Overall weight | t | 60 | seventy-five | 78 | one hundred and two | / |

| External dimensions (excluding electrical cabinets) | Mm | 9080 × 6320 × 5750 | 11080 × 6320 × 5750 | 12020 × 6820 × 5750 | 13020 × 6820 × 5750 | / |

| Typical configuration of CNC system | Standard Siemens 828D, Fanuc MF plus, optional Siemens 840Dsl | |||||

*The standard tool magazine capacity is 20 positions x 1 unit, with a maximum of 20 positions x 4 units optional.

Contact Us

address:No. 11 Xiangfeng Road, Jiangning Binjiang Development Zone, Nanjing City Sales Center

Phone:025-84950091

Customer Center Phone:025-84950092

mailbox:ningqing@163.com

Product Center

- Double pendulum head five-axis gantry milling center

- Five-axis gantry-mold machine

- High-speed crossbeam mobile gantry

- Moving column type Gantry

- Vertical/regional machining center

- High-speed profile/composite machining center

- Aerospace special equipment

- Special equipment for hand tools

- Download Center