Product Center

- Double pendulum head five-axis gantry milling center

- Five-axis gantry-mold machine

- High-speed crossbeam mobile gantry

- Moving column type Gantry

- Vertical/regional machining center

- High-speed profile/composite machining center

- Aerospace special equipment

- Special equipment for hand tools

- Download Center

Contact Us

address:No. 11 Xiangfeng Road, Jiangning Binjiang Development Zone, Nanjing City Sales Center

Phone:025-84950091

Customer Center Phone:025-84950092

mailbox:ningqing@163.com

search for

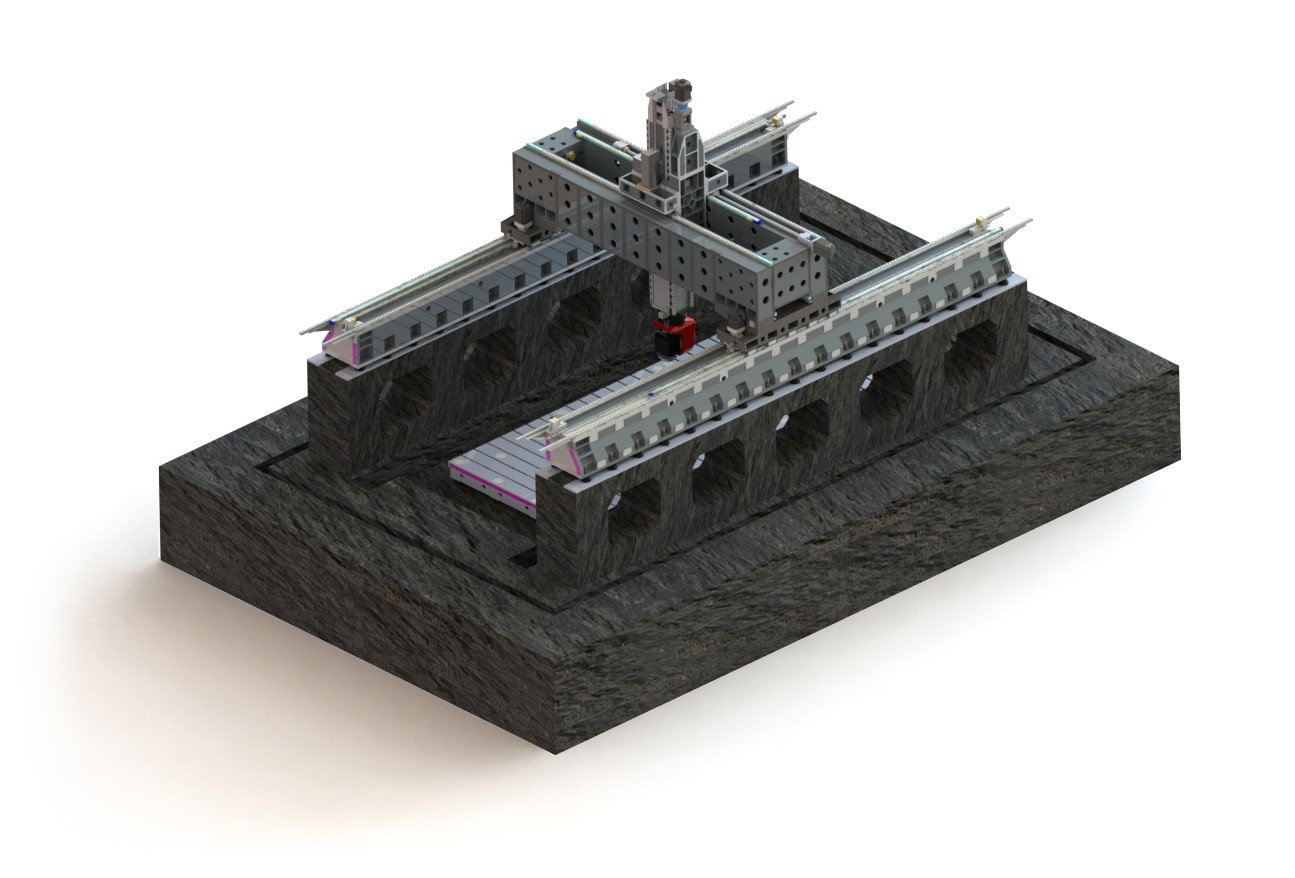

LQS series H-type

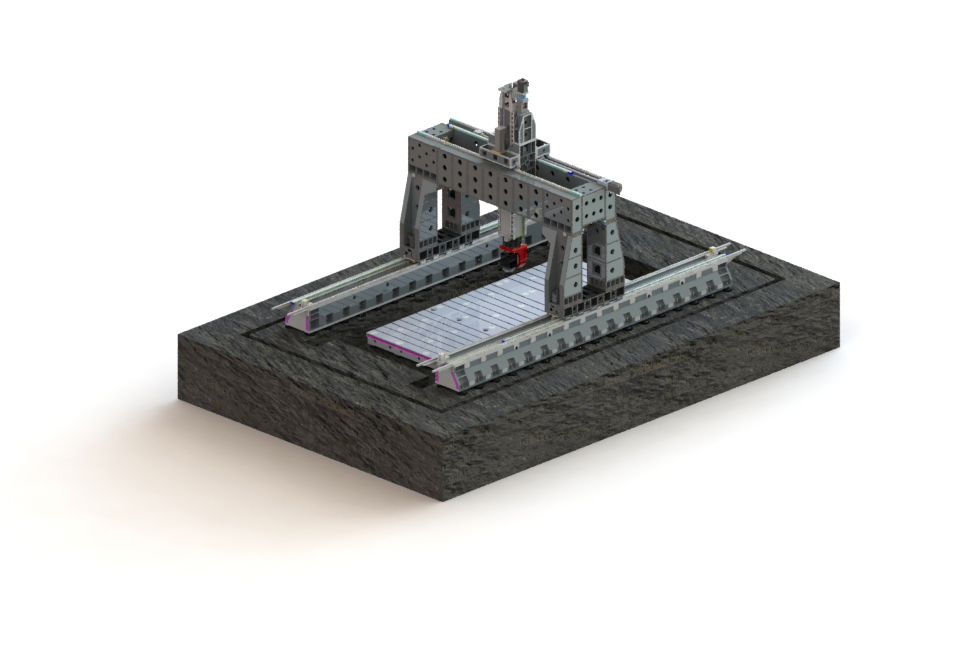

LQS series L-type

Technical parameters

technical parameter | unit | LQS5AXX25 H/L | LQS5AXX30 H/L | LQS5AXX40 H/L |

Workbench length | Mm | 4, 6, 10, 12 (the length of the workbench can be increased by 2 meters) | ||

Workbench width | Mm | two thousand and one hundred | two thousand and six hundred | three thousand and six hundred |

X-direction travel | Mm | 420062001020012200 (increase by 2 meters) | ||

Travel in Y/Z direction | Mm | 2500 × 1500 | 3000 x 1500 | 4000 × 1500 |

Guide rail form | X: Parallel distribution of four tracks on both sides Y: Vertical distribution of four tracks on top and bottom Z: Four roller tracks distributed in four directions | |||

Spindle end face to workbench | Mm | 200-1700 (customizable) | ||

Main spindle can be installed | Standard A head optional B1 head | |||

Tool magazine capacity | Standard 20 is 1 unit (maximum of 20 digits x 4 units) | |||

Maximum loading height | Mm | 1600 (customizable) | ||

Maximum loading width | Mm | three thousand and one hundred | three thousand and six hundred | four thousand and six hundred |

Rapid movement/feed rate | M/min | 30/0-15 | ||

positioning accuracy | zero point zero one | |||

Repetitive positioning accuracy | zero point zero zero five | |||

External dimensions: length (excluding electrical cabinet) | Mm | 9 meters, 11 meters, 15 meters, 17 meters (increasing by 2 meters) | ||

External dimensions: width x height (excluding electrical cabinet) | Mm | 6000 * 6500 | 6500 * 6500 | 7500 * 6500 |

Typical configuration of CNC system | 3+2 model with Siemens 828D/Five axis linkage standard with Siemens 840Dsl | |||

*The H-shaped guide rail seat adopts an integral poured concrete structure below, while the L-shaped guide rail seat adopts an elevated column structure

Parameters | Unit | LQS5AXX25 H/L | LQS5AXX30 H/L | LQS5AXX40 H/L |

Length of worktable | mm | 4,6,10,12 (table length can be increased by 2 m) | ||

Width of worktable | mm | 2100 | 2600 | 3600 |

X travel | mm | 4200,6200,10200,12200 (increase by 2 m) | ||

Y/Z travel | mm | 2500×1500 | 3000×1500 | 4000×1500 |

Spindle nose to table | mm | 200-1700 (customizable) | ||

Spindle can be installed | A head B1 head / optional | |||

Tool magazine capacity | 20,Max:20×4units/optional | |||

Max loading height | mm | 1600(customizable) | ||

Max loading width | mm | 3100 | 3600 | 4600 |

Rapid speed | m/min | 30/20/20 | ||

Feeding speed | m/min | 0-15 | ||

Positioning accuracy | 0.01 | |||

Repeatability accuracy | 0.005 | |||

Dimension:L (without clectric cabinet) | mm | 9m, 11m, 15m, 17m (increase by 2 m) | ||

Dimension:WxH (without clectric cabinet) | mm | 6000×6500 | 6500×6500 | 7500×6500 |

Control system Siemens 828D for3+2 type/Siemens ONE for 5-axis simultancous as standard | ||||

Technical parameters

technical parameter | unit | LQS5AXX25 H/L | LQS5AXX30 H/L | LQS5AXX40 H/L |

Workbench length | Mm | 4, 6, 10, 12 (the length of the workbench can be increased by 2 meters) | ||

Workbench width | Mm | two thousand and one hundred | two thousand and six hundred | three thousand and six hundred |

X-direction travel | Mm | 420062001020012200 (increase by 2 meters) | ||

Travel in Y/Z direction | Mm | 2500 × 1500 | 3000 x 1500 | 4000 × 1500 |

Guide rail form | X: Parallel distribution of four tracks on both sides Y: Vertical distribution of four tracks on top and bottom Z: Four roller tracks distributed in four directions | |||

Spindle end face to workbench | Mm | 200-1700 (customizable) | ||

Main spindle can be installed | Standard A head optional B1 head | |||

Tool magazine capacity | Standard 20 is 1 unit (maximum of 20 digits x 4 units) | |||

Maximum loading height | Mm | 1600 (customizable) | ||

Maximum loading width | Mm | three thousand and one hundred | three thousand and six hundred | four thousand and six hundred |

Rapid movement/feed rate | M/min | 30/0-15 | ||

positioning accuracy | zero point zero one | |||

Repetitive positioning accuracy | zero point zero zero five | |||

External dimensions: length (excluding electrical cabinet) | Mm | 9 meters, 11 meters, 15 meters, 17 meters (increasing by 2 meters) | ||

External dimensions: width x height (excluding electrical cabinet) | Mm | 6000 * 6500 | 6500 * 6500 | 7500 * 6500 |

Typical configuration of CNC system | 3+2 model with Siemens 828D/Five axis linkage standard with Siemens 840Dsl | |||

Contact Us

address:No. 11 Xiangfeng Road, Jiangning Binjiang Development Zone, Nanjing City Sales Center

Phone:025-84950091

Customer Center Phone:025-84950092

mailbox:ningqing@163.com

Product Center

- Double pendulum head five-axis gantry milling center

- Five-axis gantry-mold machine

- High-speed crossbeam mobile gantry

- Moving column type Gantry

- Vertical/regional machining center

- High-speed profile/composite machining center

- Aerospace special equipment

- Special equipment for hand tools

- Download Center