Product Center

- Double pendulum head five-axis gantry milling center

- Five-axis gantry-mold machine

- High-speed crossbeam mobile gantry

- Moving column type Gantry

- Vertical/regional machining center

- High-speed profile/composite machining center

- Aerospace special equipment

- Special equipment for hand tools

- Download Center

Contact Us

address:No. 11 Xiangfeng Road, Jiangning Binjiang Development Zone, Nanjing City Sales Center

Phone:025-84950091

Customer Center Phone:025-84950092

mailbox:ningqing@163.com

search for

1. Full casting body, good rigidity and stability.

2. ram moving high-speed operation, stability is better than column moving.

3. X-way slide plate is arranged in high and low steps, which greatly increases the overall strength of the machine.

4. Skeletonized working table is conducive to chip removal

5. The sheet metal is reasonably designed to effectively prevent aluminum chips and cutting fluid from splashing during high-speed machining, which meets the requirements of environmental protection.

6. X105 series X-direction adopts double gantry structure with large supporting area and strong structural rigidity, which can realize the rapid movement of Y-direction, avoiding the shortcomings of the traditional column mobile Y-direction with slow moving speed and center of gravity shift. Compared with the single-arm gantry structure Y furthest end of the rigidity and high precision.

7. All three axes guide rails adopt Japan THK heavy-duty linear guide rails, and the rack and pinion and reducer adopt German Alpha high-precision rack and pinion.

Difference between casting structure and welding structure

Traditional machine tools generally use casting body, the reason is that the casting has good pressure resistance, vibration absorption and stability, as long as the reasonable aging treatment, can effectively release the stress, to ensure that the machine's long-term accuracy. Welded bed as a lightweight design, in the international are also commonly used, but the welded bed needs good anti-deformation structural design, need complex aging treatment, and suitable processing technology, otherwise the accumulated stress in the structure will slowly release, resulting in the gradual deformation of the machine tool. Many domestic machine tool companies in order to reduce costs to improve the time, steal the concept of high-grade welded bed, misleading many domestic consumers. For high-speed machine, due to high speed and high acceleration, the body needs to withstand high impact, so still need to use the structural strength and vibration absorption better casting structure.

Aerospace Composite Dust Extraction

This series of machine tools can be used for aerospace composite material processing, adopting double-layer area dustproofing, the first layer is vacuuming inside the door frame, and the second layer is the whole closed vacuuming, which is effective in vacuuming.

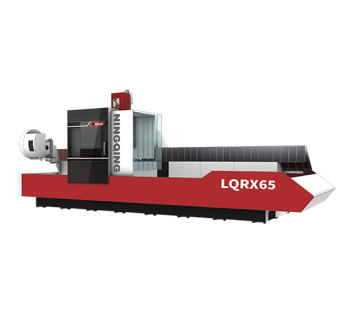

Parameters | Unit | LQRX65 | LQRX105 | Parameters | Unit | LQRX65 | LQRX105 |

Worktable | mm | 5500/7500/11000 /13000/15000×600 | 6500/8500/13000 /15000/17000×1000 | Dimension | m | 6/8/11.5/13.5/ 15.5×2.2×2.8 | 7/9/13.5/15.5/ 17.5×2.6×2.8 |

T-slot | mm | 4×18 | 6×18 | Feeding speed | m/min | 20 | |

Table load | t | 0.8/1/1.6/1.8/2 | 0.8/1/1.6/1.8/2 | Rapid speed | m/min | 40/30/30 | |

X travel | mm | 4500/6500/10000 /12000/14000 | 4500/6500/11000 /13000/15000 | Tool magazine capacity | 24 | ||

Y/Z travel | mm | 600×500 | 1000×500 | Tool change time | s | 4 | |

Guide way | 3 axe linear guide, 2 rollers in Z axis | 3 axe linear guide, 4 rollers in Z axis | Positioning accuracy | mm | 0.02 | ||

Spindle nose to table | mm | 80-580 | 150-650 | Repeat accuracy | mm | 0.01 | |

Spindle table | BBT40 | Machine weight | t | 16/19/25/28/32 | 23/28/38/43/48 | ||

Spindle speed | rpm | 15000 | Total power | Kw | 22 | ||

Spindle motor | Kw | 8.4 | Control system | Siemens、Fanuc 0i MF | |||

Contact Us

address:No. 11 Xiangfeng Road, Jiangning Binjiang Development Zone, Nanjing City Sales Center

Phone:025-84950091

Customer Center Phone:025-84950092

mailbox:ningqing@163.com

Product Center

- Double pendulum head five-axis gantry milling center

- Five-axis gantry-mold machine

- High-speed crossbeam mobile gantry

- Moving column type Gantry

- Vertical/regional machining center

- High-speed profile/composite machining center

- Aerospace special equipment

- Special equipment for hand tools

- Download Center