Knowledge Lecture - Localization rate reaches 60%, unveiling the C919 industry chain of domestically produced large aircraft

Knowledge Lecture | Localization rate reaches 60%, unveiling the C919 industry chain of domestically produced large aircraft

The following article is sourced fromWorld of Electronic Engineering

On the noon of May 28th, with the successful landing of China Eastern Airlines MU9191 at Beijing Capital Airport and passing through the "Watergate" symbolizing the highest etiquette of civil aviation, the domestically produced large aircraft C919 also successfully completed its first commercial passenger flight.

Due to its complex and cutting-edge technology, the manufacturing of large aircraft is renownedThe Pearl on the Crown of Industry. Organisation for Economic Co operation and Development(OECD)Put the large aircraft manufacturing industry at the forefront of the knowledge economy industry. The success of this commercial flight proves the stability and reliability of the C919 in commercial passenger flights, as well as the maturity of related technology fields for domestically produced large jet civil aircraft.

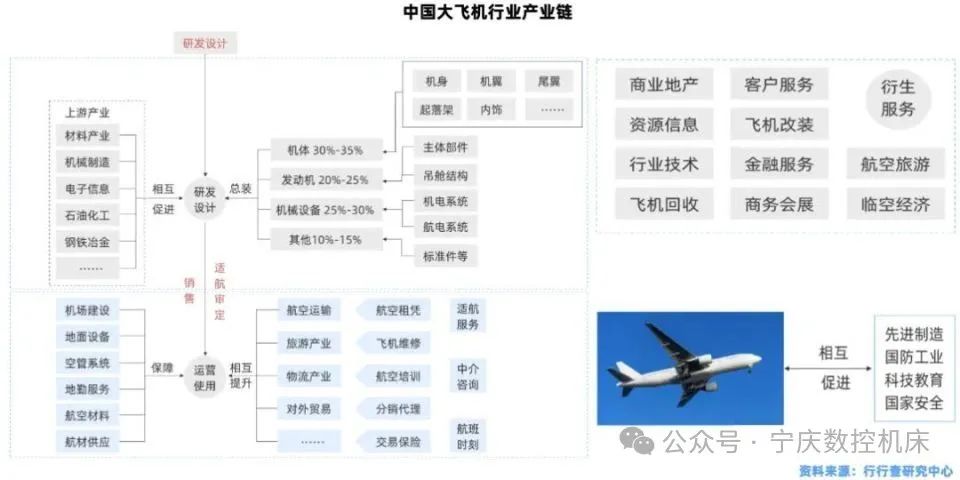

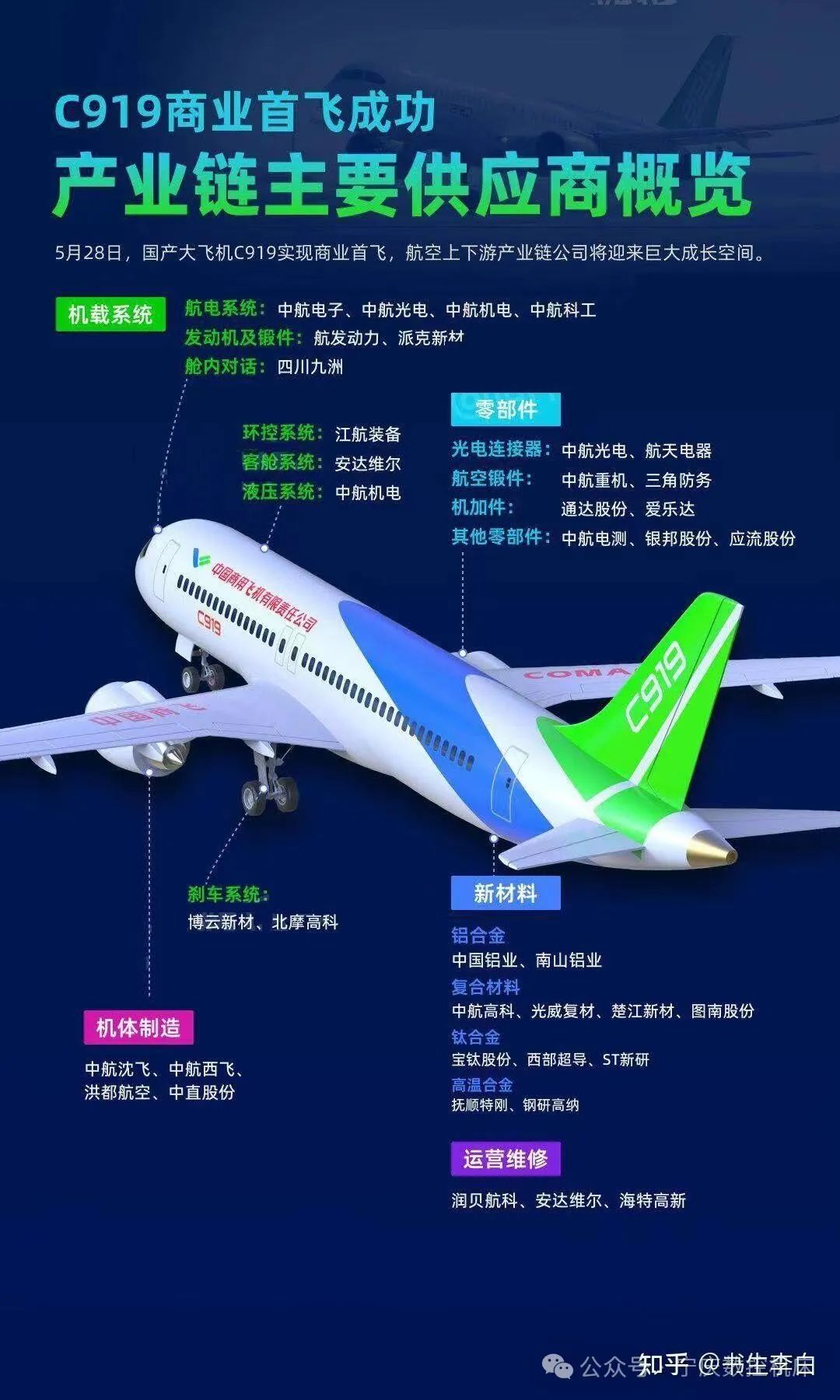

From the perspective of the industrial chain, the C919 industry chain is complex and has high added value, involving complex processes from design and development, production and manufacturing to operation and maintenance.

The localization rate of C919 large aircraft has reached 60%

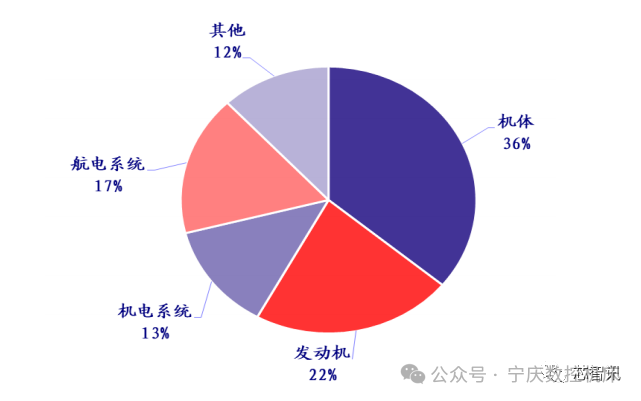

According to the Forward Industry Research Institute, the cost composition of civil aviation aircraft mainly consists of the body, engine, electromechanical system, avionics system, and other parts, with each part accounting for approximately 36%, 22%, 13%, 17%, and 12% of the value. Based on an estimated annual sales revenue of 8 billion US dollars for the C919, the value of the five systems mentioned above is approximately 28.8 billion, 17.6 billion, 10.4 billion, 1.36 billion, and 960 million US dollars.

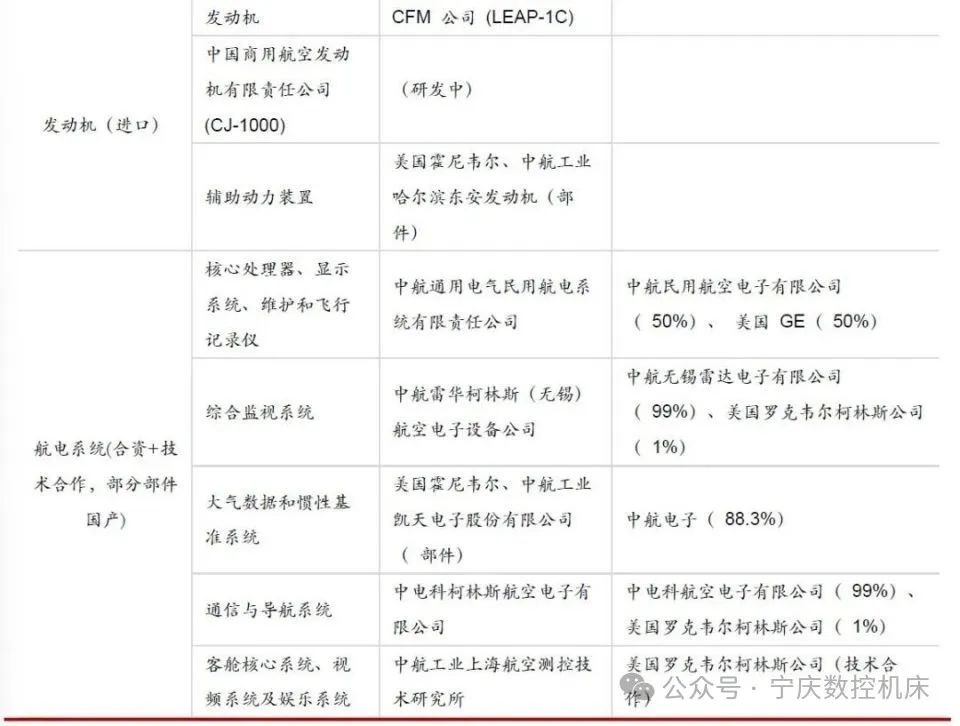

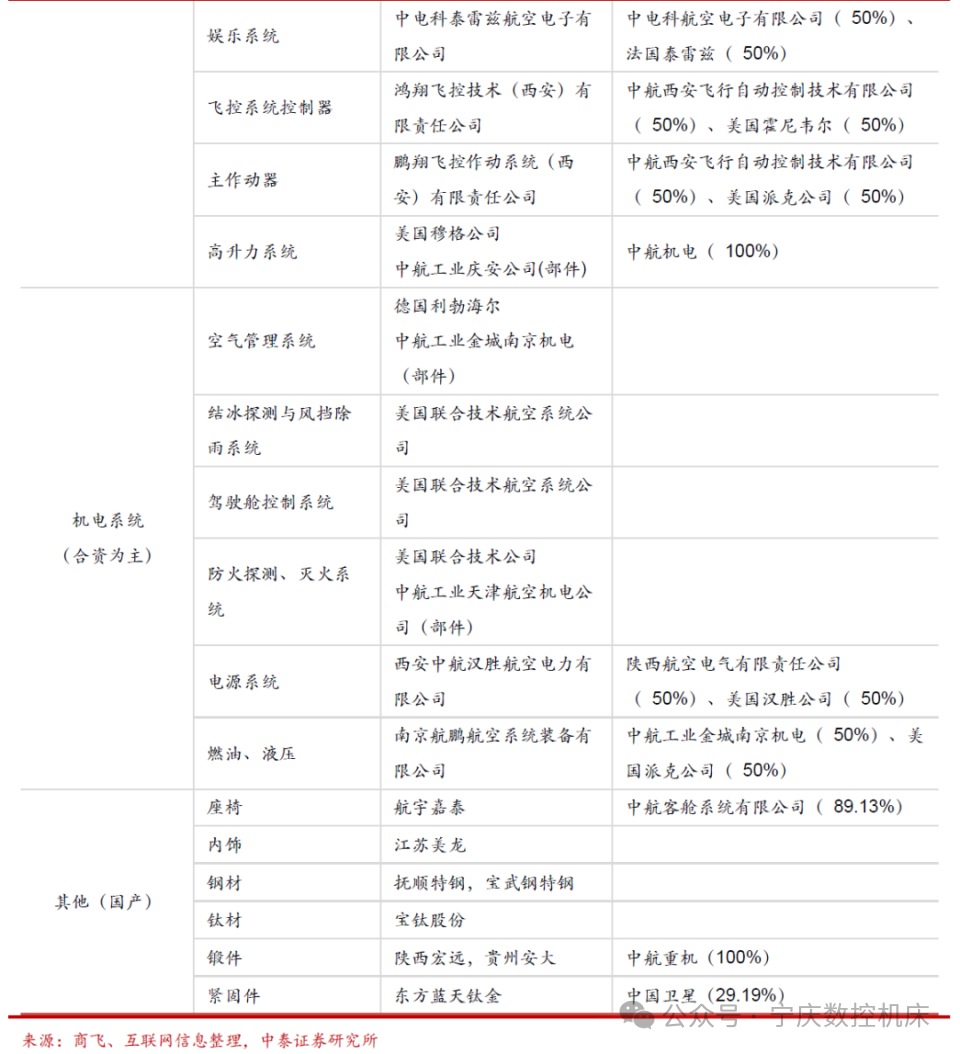

In terms of onboard systems, they are mainly divided into avionics systems and electromechanical systems, which are the core of aircraft flight control. Due to high safety requirements, the types, quantities, and complexity of onboard systems for passenger aircraft are very high. The main form of supply for C919 is in the form of joint ventures. AVIC's subsidiaries have established multiple joint ventures with foreign companies to jointly provide electromechanical and avionics equipment, but most of the assets have not yet been injected into the listed company.

In terms of engines, the C919 is currently being purchasedUS GEThe LEAP-1C engine from CFM, a joint venture with the French Safran Group, while the planned domestic aircraft engine "CJ-1000A" is still in the development stage. According to reports, Aero Engine Power participated in the development of the domestically produced CJ-1000 engine.

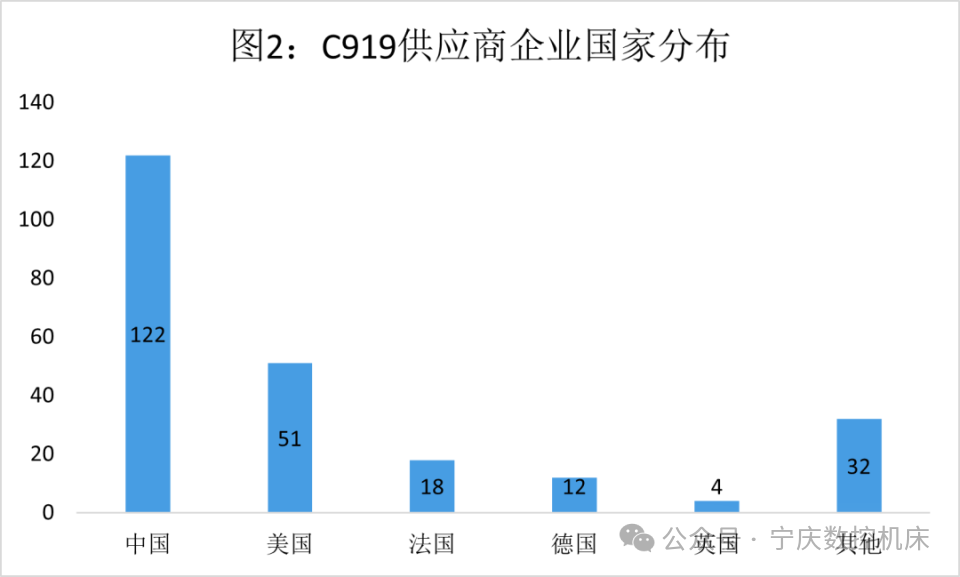

The localization rate of C919 has reached about 60%. This "number" is mainly based on the cost composition of the ten core systems of large aircraft (structural system 36%, engine system 22%, avionics system 17%, electromechanical system 13%, etc., and the remaining 12% are landing gear, hydraulic, fuel and environmental control systems), combined with the proportion of products provided by each enterprise in the "main supply mode".

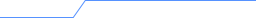

Specifically, the body parts of domestic passenger aircraft, including the nose, fuselage, wings, cabin doors, radar covers, etc., are independently completed by our domestic suppliers, including AVIC Chengfei, XAC, Hongdu Airlines, Shenyang Aircraft Corporation, Changfei, Hafei, and research institutes within the AVIC system.

The industrial chain behind large aircraft

China CITIC Securities pointed out that the body of the C919 aircraft is mainly supplied by domestic suppliers, including Hongdu Airlines and AVIC AircraftAVIC Shenyang Aircraft CorporationThree listed companies monopolize the aircraft body business. Calculated based on a value to volume ratio of 35%, assuming a price of $50 million per C919 and a manufacturing value of $17.5 million, with three listed companies accounting for approximately $10 million. According to COMAC's latest forecast, from 2020 to 2039, the global demand for narrow body passenger aircraft will be 20000, with China's demand for 4620, averaging 231 aircraft per year. If calculated based on COMAC's annual design capacity of 150 aircraft, it is expected to bring an annual increase of 2.625 billion US dollars (approximately 18 billion RMB) to the listed companies of the whole machine factory.

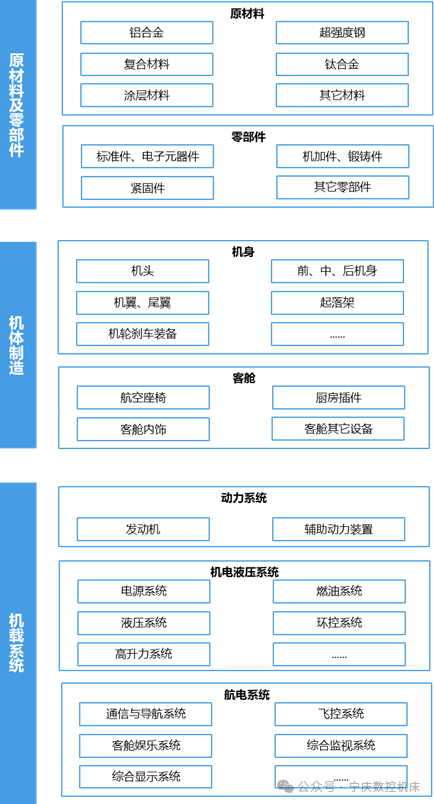

The manufacturing of large aircraft is mainly divided into three stages: raw materials and components, body manufacturing, and onboard systems. The raw materials and components stage includes the manufacturing of metal materials and composite materials, as well as the processing of standard parts, machined parts, and other components. The body manufacturing stage includes the manufacturing of the fuselage and cabin. The onboard systems include power systems, electromechanical hydraulic systems, and avionics systems. The breakdown of each stage is shown in the following figure:

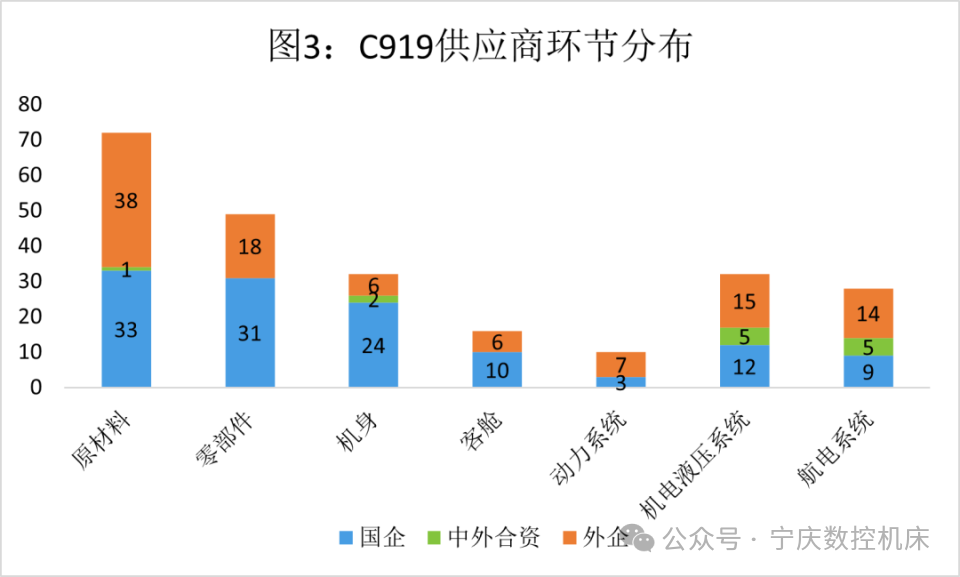

The localization of raw materials is advancing rapidly, with domestic suppliers accounting for nearly half of the total. The main raw materials include aluminum alloy, composite materials, titanium alloy, high-strength steel, etc. The main domestic suppliers of aluminum alloys are Aluminum Corporation of China and Nanshan Aluminum Industry; The main suppliers of titanium alloy products include Baotai Co., Ltd., Western Superconductor, and Western Materials; High strength steel suppliers are represented by Baosteel and Fushun Special Steel; The main composite material suppliers are AVIC High Tech, Zhongfu Shenying, Guangwei Composite Materials, Hengshen Co., Ltd., and Chujiang New Materials.

There are numerous domestic participating enterprises in the parts and components sector, forming a market pattern dominated by enterprises within the system and effectively supplemented by private enterprises. Components mainly include standard parts, electronic components, forged castings, machined parts, etc. Component processing is the foundation of aircraft body manufacturing and onboard equipment production, characterized by high technical barriers, high qualification barriers, and high financial barriers. At present, domestic suppliers of C919 components are mainly enterprises belonging to aerospace and military systems, including AVIC Optoelectronics, Aerospace Electrical, AVIC Heavy Machinery, etc; Private enterprises can effectively supplement, including Triangle Defense, Tongda Shares, Aileda, Maixinlin, etc.

The manufacturing process of the aircraft body is led by domestic aviation host manufacturers, with the highest localization rate. The main components of aircraft manufacturing include the nose, front fuselage, middle fuselage (including central wing), middle and rear fuselage, rear fuselage, outer wings, vertical tail, flat tail, and movable surface. The body manufacturing is the highest localization rate of C919, mainly undertaken by domestic suppliers led by aviation host manufacturers. The main suppliers of the C919 aircraft body include AVIC West, Shenyang Aircraft Corporation, Hongdu, Hafei, Changfei, Jinan Institute of Special Structures (637 Institute), Aerospace Changying, Zhejiang Xizi, etc.

The localization of airborne systems has the greatest potential for improvement, and domestic enterprises are catching up through joint ventures and other means. The onboard system mainly includes power system, avionics system, electromechanical hydraulic system, etc. The airborne system is the segment with the highest proportion of foreign-funded enterprises in the C919, and also the segment with the highest number of Sino foreign joint ventures. Domestic enterprises are rapidly catching up through joint ventures, project collaborations, and independent research and development to increase the localization rate of airborne systems. At present, the C919 aircraft uses the LEAP-1C engine from CFM International, and China Aviation Industry Corporation is developing the CJ1000A engine, which is expected to promote the localization of commercial aviation engines; The safety critical systems in the avionics system are provided by foreign companies such as Rockwell Collins and Honeywell, and joint ventures have been established. Shanghai Aviation Electric Co., Ltd., a subsidiary of AVIC Electronics, a listed domestic company, participated in the board development of the avionics system; Suppliers of electromechanical hydraulic systems include foreign companies, joint ventures, and domestic enterprises. Among them, listed companies AVIC Aircraft Electronics Co., Ltd. Aviation Industry Qing'an and Shaanxi Aviation Electric Co., Ltd. respectively participated in the supporting work of high lift systems and power systems.

Source of information on the domestic large aircraft industry chain: Xingxingcha

In terms of electronic components, the C919's electronic system is complex and large-scale, with a high demand for electronic components.

According to previously disclosed information, in May last year, the HKM9000 graphics processor (GPU) independently developed by the Aerospace Industry Computing Institute's Xiangteng Microelectronics Company passed the joint test verification of the cabin display and control system of the domestically produced civil aircraft C919, officially entering the airworthiness certification stage.

This chip uses an independent architecture and can be optimized and adapted at multiple levels in the application adaptation process, including algorithm design, logic implementation, assembly instructions and compilers, underlying software drivers, and middleware. Especially in special application scenarios such as Chinese character display, dashboard display, texture mapping, etc., optimization has been achieved. The measured results generally show a 20% improvement in performance compared to commercial grade chips, and the performance in dashboard and other scenarios can be increased by 2-3 times.

After the commercial maiden flight of the C919, Changhong Holdings' official WeChat account published an article claiming the main/APU battery pack carried on the C919.

According to Changhong's official introduction, the main/APU battery pack this time is the first product in China to obtain CTSOA certification, with excellent low-temperature resistance and the ability to work normally in an environment of minus 40 ℃.

At the same time, it has a maximum instantaneous discharge current of over 800A, which meets the emergency start requirements of large aircraft engines, and its comprehensive performance indicators have reached the international advanced level.

It is reported that the battery pack is an emergency power source for starting the engine and onboard equipment, ensuring the safe takeoff, flight, and landing of the aircraft. Therefore, it has extremely high reliability requirements and high research and development costs.

Previously, the Boeing 787 was forced to be grounded due to a malfunction in the GS Yuasa battery it was equipped with.

Industry insiders believe that the C919 project can better meet the commercial operation needs of civil aviation by increasing the localization rate.

Welcome to exchange ideas in the comment section below

Disclaimer: This article is reproduced online and the copyright belongs to the original author. If the videos, images, or text used in this article involve copyright issues, please inform us as soon as possible. We will confirm the copyright based on the proof materials you provide and pay the remuneration according to national standards or immediately delete the content! The content of this article is the opinion of the original author, which does not mean that this official account agrees with his opinion and is responsible for its authenticity.

Scan QR code

Follow more exciting events