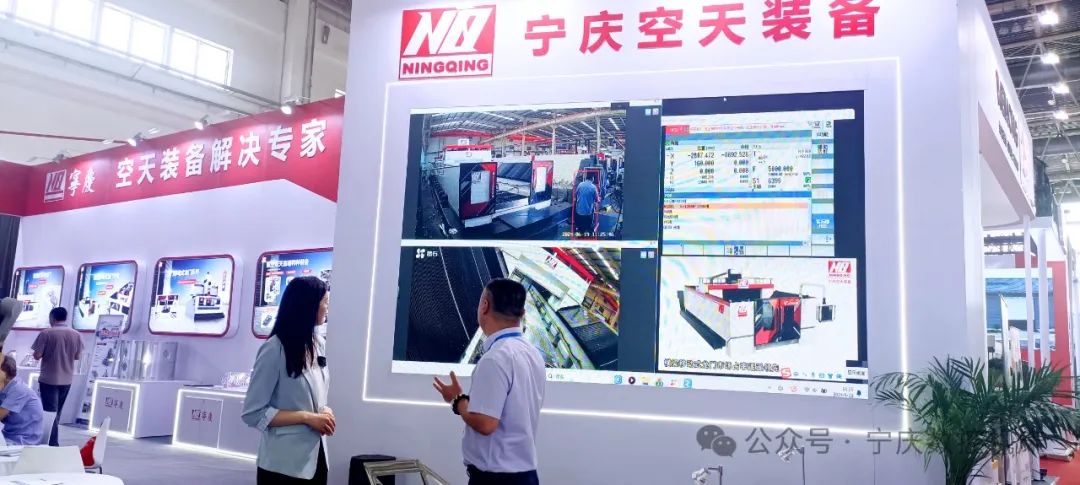

The 27th Qingdao International Machine Tool Exhibition

June 26-30

Qingdao International Expo Center

No. 7-1, Wenquan 2nd Road, Jimo Wenquan Town, Qingdao City (Binhai Avenue)

Ning QingS1-B101Display comprehensively

The above is the exhibition site in Beijing

1

Technological advantages and innovation points

1. An elevated bridge structure that combines high dynamic performance with high metal removal rate. Fixed workbench, capable of carrying large loads

2. Direct drive clamp arm dual swing head, combining high torque and high precision performance

3. Symmetrical crossbeam structure design within the box, evenly subjected to cutting forces, reduces overturning

4. Dual drive traction, X and Y directions through gear rack and double motor clearance

5. Large sized roller slider ensures high rigidity

6. Dynamic gap compensation function throughout the entire lifecycle

7. Excellent protective measures effectively isolate contamination from chip fragments and other processing debris

8. Five axis 3D real-time collision prevention, built-in based on SiemensSports chainThe S02 anti-collision system incorporates a simplified 3D model with a 1:1 scale to the actual machine tool in the CNC system, enabling real-time protection of the machine tool in space

9. Virtual machine tool solution, creating machine tools for customersDigital twinsVisualize every moment of the production process

Strong rigidity, high speed and precision, large load-bearing capacity, and small footprint

Box type crossbeam, substitute for imported models

This machine tool is capable of high-speed rough and precision machining of various large and complex molds, parts, etc. The machine tool has the ability to complete five axis five linkage machining of workpieces in one loading, and is suitable for processing large and medium-sized complex parts in industries such as aerospace, molds, automobiles, railways, and ships. It has high processing efficiency and can achieve high surface quality of parts.

2

Product parameters

Machine tool load-bearing capacity: up to 30T

Journey: 3200 × 2000 × 1000mm

Feed width: up to 2400mm

Fast moving speed: up to 40m/min, high precision machining efficiency

ScrewTrack: All use THK brand

Double swing head: Italy 42/55KW, 24000rpm HSKA63 high-precision swing head, high smoothness

Spindle speed: 24000rpm

Standard full closed-loop configurationGrating rulerLaser alignment device

Precision synchronous dual drive technology, good servo characteristics, high smoothness, and high contour accuracy

Especially suitable for high smoothness machining of precision molds and high-speed precision machining of aerospace products,Already maturely applied in the mold and aerospace industries

System: Siemens ONE/Heidenhain/Central China

Looking forward to all friendsVisit usNing Qing

S1-B101 booth

![]()

Scan QR code

Follow more exciting events