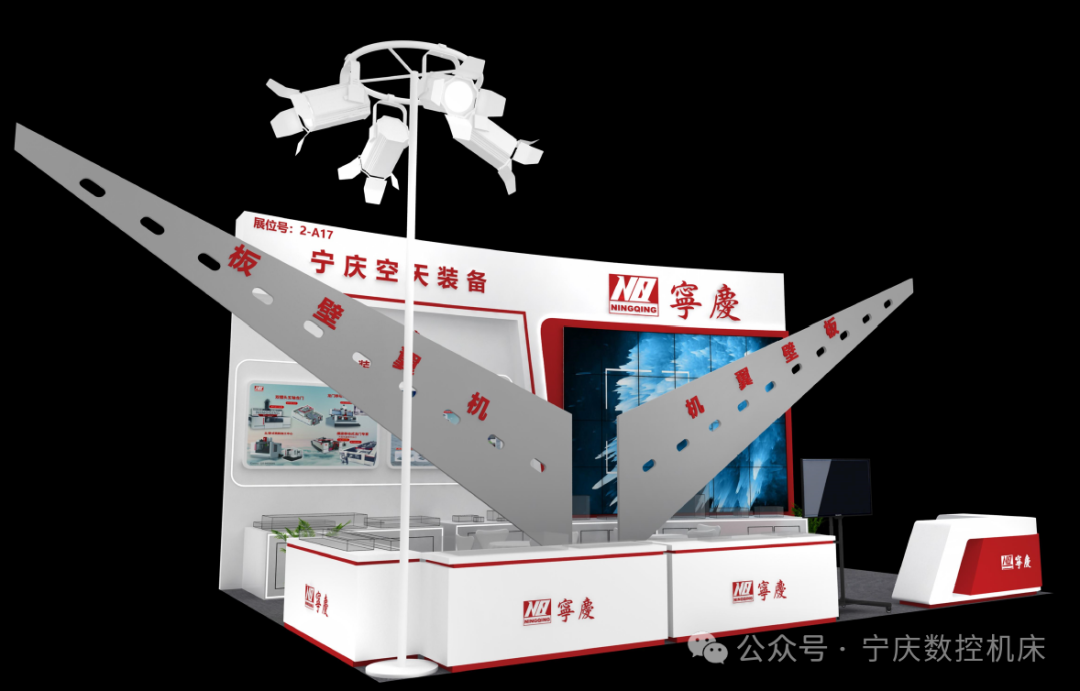

Exhibition Attention - July 18-20, 2024 Xi'an Advanced Manufacturing Expo cordially invites you to come!

Exhibition Focus | July 18-20, 2024 Xi'an Advanced Manufacturing Expo cordially invites you to come!

Exhibition content

Exhibition Name:

China (Xi'an) Military Science and Technology Industry Expo

Exhibition location:

Halls 1, 2, and 4 of Xi'an International Convention and Exhibition Center

(1399 Huizhan 1st Road, Baqiao District)

Exhibition time:

July 18th to July 20th, 2024

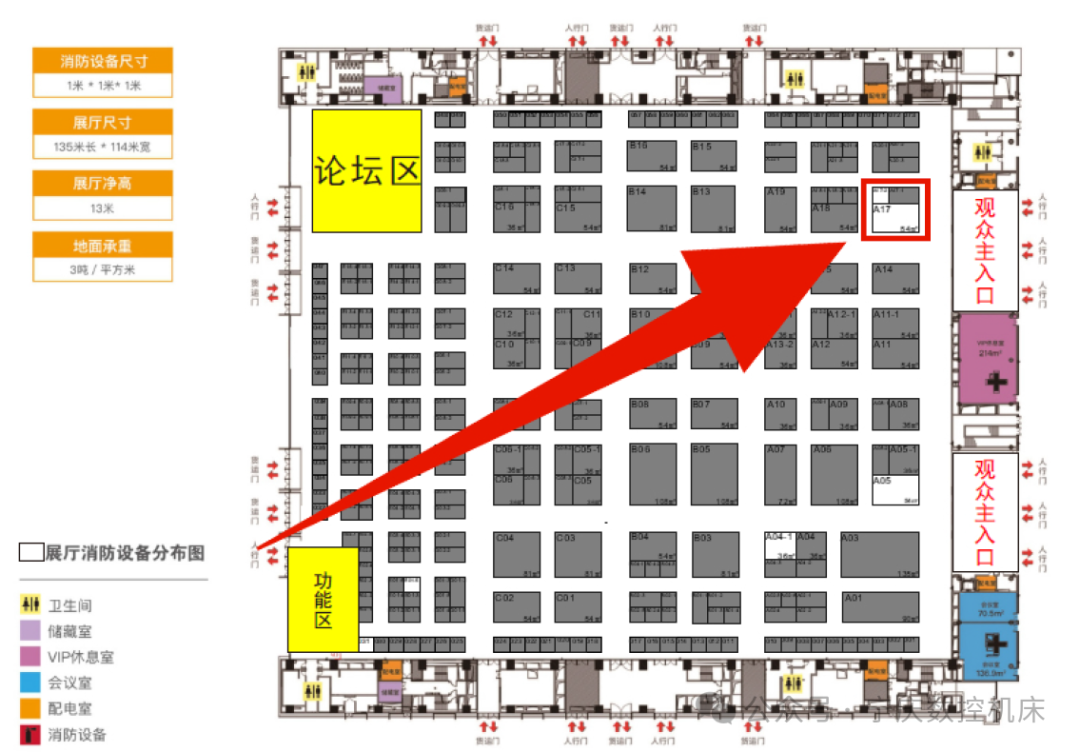

Ning Qing at A2-17 (booth number)

Looking forward to your visit!

Nanjing Ningqing CNC Machine Tool Manufacturing Co., Ltd

Nanjing Ningqing CNC Machine Tool Manufacturing Co., Ltd. was established in 2004 and can provide customers withHigh end equipment, processing services, digital production lines, and complete process solutions.

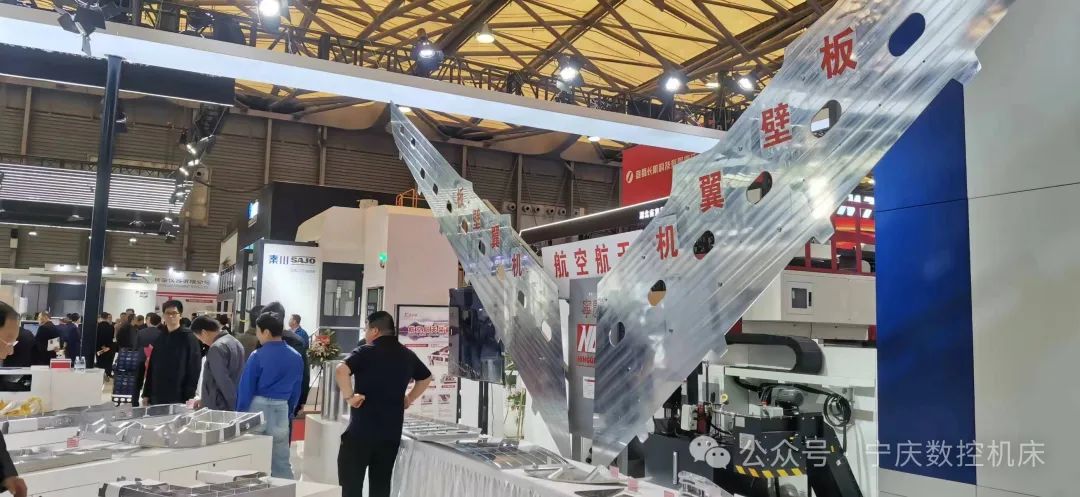

Batch use of company equipmentC919、ARJ21、 Manufacturing of core components for Y-20, J-20, and carrier rocketsThe company's crossbeam mobile gantry has the highest domestic market share and has become a leading enterprise in aerospace intelligent manufacturing equipment.

Product Display

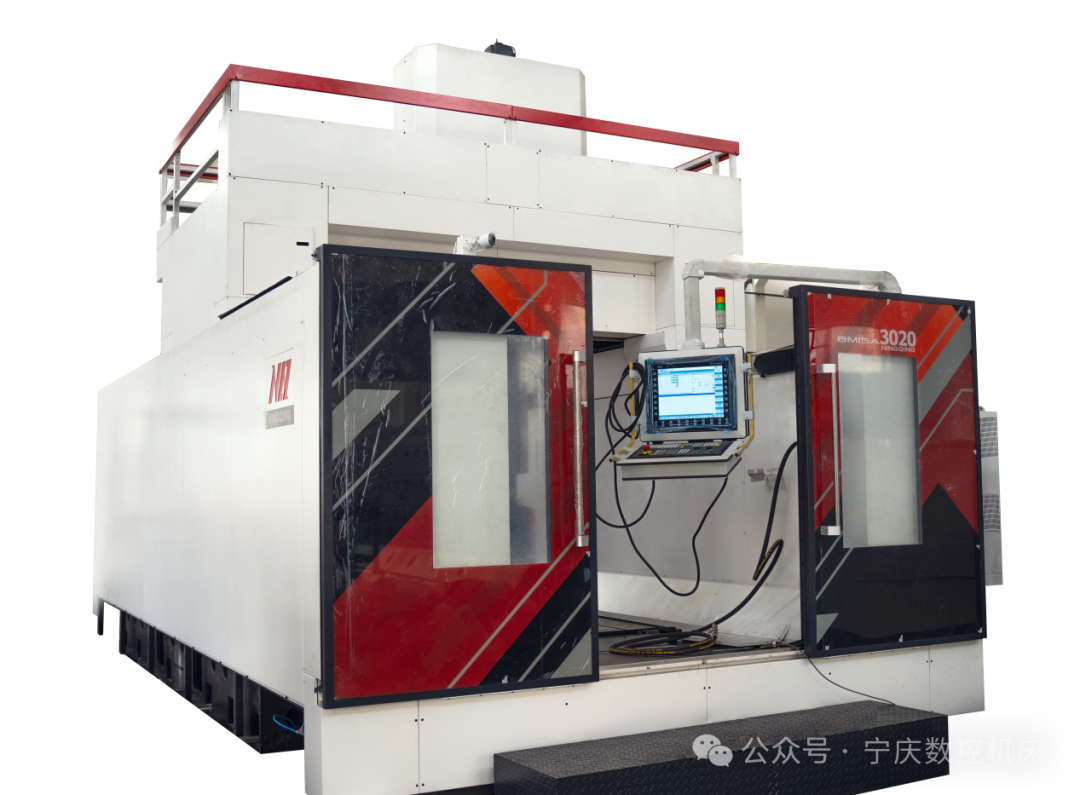

01BMI5A3020 · Horizontal beam mobile five axis linkage CNC gantry machining center

Strong rigidity, high speed and precision

Large load capacity and small footprint

Box type crossbeam, substitute for imported models

Technical advantages:

1. Elevated bridge structure combining high dynamic performance and high metal removal rate. 2. Fixed workbench with large load-bearing capacity;

3. Direct drive clamp arm dual swing head, combining high torque and high precision performance;

4. The symmetrical crossbeam structure design in the box ensures even cutting force and reduces overturning;

5. Dual drive traction, with backlash reduction in the X and Y directions through gear racks and dual motors;

6. Large sized roller slider ensures high rigidity;

7. Dynamic gap compensation function throughout the entire lifecycle;

8. Excellent protective measures effectively isolate contamination from chip fragments and other processing debris;

9. Virtual machine tool solution, creating a digital twin of machine tools for customers, visualizing every moment of the production process;

10. Proficient in efficient roughing and high-precision machining of large aerospace components that are difficult to process and prone to deformation;

Technical parameters:

Maximum load capacity: up to 30T

X/Y/Z travel: 3200 × 2000 × 1000mm

Feed width: up to 2400mm

Fast moving speed: 40/40/20m/min

Spindle speed: 24000rpm

Positioning accuracy: 0.01mm

Repetitive positioning accuracy: 0.005mm

Whole machine weight: 42t

Dimensions (excluding electrical cabinet): 7400 × 4700 × 6200mm

System: Siemens ONE/Heidenhain/Huazhong

02GMI2516 · Heavy cutting gantry mobile CNC gantry machining center

High rigidity, heavy cutting, strong versatility

Strong load-bearing capacity and high torque

Technical advantages:

1. Longmen mobile structure, fixed workbench, large load-bearing capacity;

2. The X-axis guide rail is placed below the ground and equipped with a walkable protective cover;

3. Multiple large-sized roller sliders with dual drive traction on each axis ensure high rigidity;

4. Each axis adopts the proprietary composite guide rail technology independently developed by our company;

5. The slider is made of ball milled cast iron, which has been quenched and finely ground to provide extremely strong rigidity;

6. The guide track adopts a steel strip sealing form;

7. Multiple interchangeable milling heads, tool changing systems, and other accessory options are available;

8. Heavy cutting processing for extra large, extra heavy, and wide width parts;

Technical parameters:

Maximum load capacity: 15T

Workbench area: 2500 × 1400mm

X/Z travel: 2500 × 800mm

Maximum loading width: 1600mm

Guide rail form: precision synchronous drive on both sides in the X direction, supported by two straight guide rails and rectangular rails on both sides, parallel distribution of double track rails in the Y direction supplemented by strong support of hard guide rails, and Z-direction hard rail with side double track combined square sliding pillows

Cutting feed rate: 0-15m/min

Fast moving speed: 15m/min

Positioning accuracy: 0.01mm

Repetitive positioning accuracy: 0.005mm

Whole machine weight: 20T

Dimensions (excluding electrical cabinet): 6100 × 4700 × 3700mm

Standard configuration includes Siemens 828D, Fanuc 0i MF plus, and optional Siemens ONE

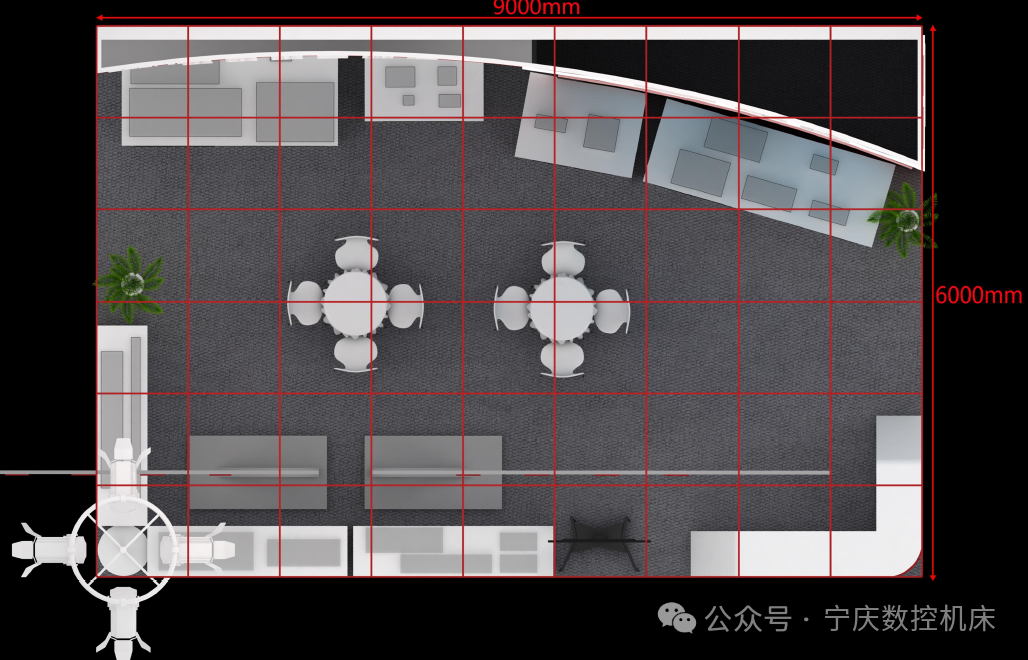

Booth Floor Plan

Scan QR code

Follow more exciting content